Description

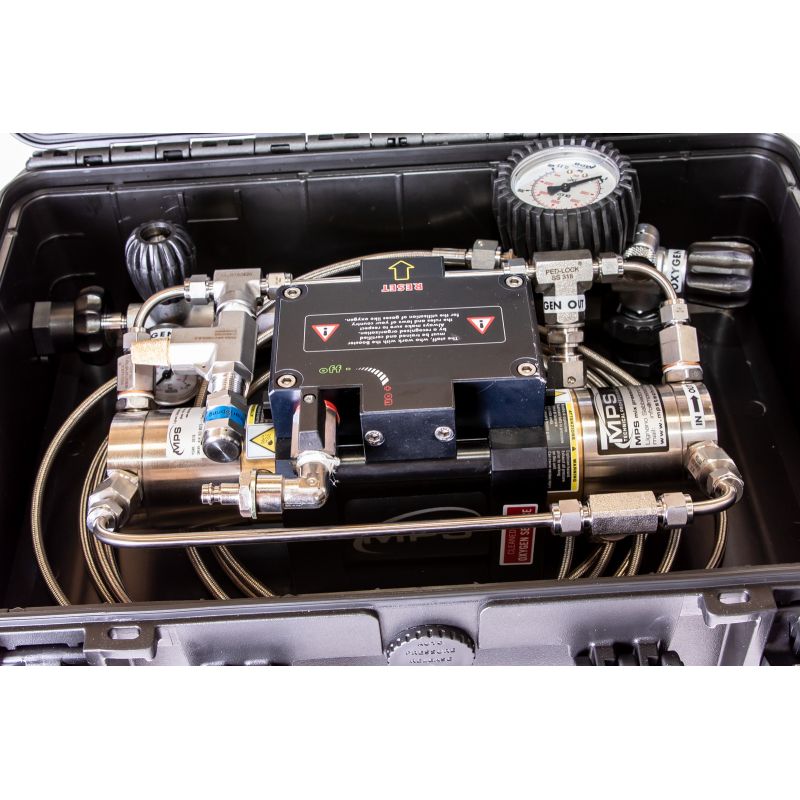

MPS TECHNOLOGY BOOSTER C1X SPORT Line

Booster for sport divers, especially in CCR. High performances, reliability and security are his master words.

The benefits of this booster:

Performance: Filling a 3L cylinder from 100b to 220b in 1min30 from a B50 oxygen source at 100b,

Maintenance once a year,

Robustness and reliability,

Protection of the operator,

Supplied completely ready to use.

Overall our boosters include the same security systems:

Heat management: because our boosters are designed for compressed gas, we cool the HP gas. Each time-driven air vents, it produced cold by his decompression, we send this cold gas around the high-pressure chamber to cool the piston chamber and blower gas. This is very different from the remarked Chinese hydraulic pumps that have no temperature management (normal, a liquid can’t be compressed and so does not produce heat), aside finding themselves completely frosted and the second becomes so hot it can’t be touched,

Speed management: the user is able to regulate the number of strokes per minute speed by adjusting the MP of engine air valve,

Deflagration absorption: The high-pressure cylinder base contains a buffer volume that allows reducing the impact of a deflagration in the high-pressure cylinder by 10,

Filtration of oxygen/helium: because the gas manufacturer use massively grease in their industrial systems, we filter gas entering the booster via a filtration stone in the inlet connector, this little stone is to change once or twice a year according to the use of the booster (€2 approx.),

Keep clean the system: we have positioned two non-return valves on each side of the HP chamber, your block gas can not go back to the HP chamber, and the HP gas can not go back in your gas cylinder source,

The gas safety: pushed gas cannot be mixed with the engine gas, two vent stones based on the HP part allow the high-pressure gas to evacuate if a stroke seal is broken,

Programming the booster: it is possible to configure your booster so that it stops working when the required HP pressure is reached (short training),

Specific materials: our boosters are made from serious materials

– the cooling chamber is made of stainless steel 3 mm thickness, reinforced at the base by a 10 mm of Ergal ring,

– our hoses are stainless steel braided with an inner Teflon coating. This allows to never have a deposit of contaminant in the hose unlike the standard rubber hose which inner roughness storing contaminants are regularly the place of flame departure,

– the sealing of the piston is performed with an assembly of o-rings and flat gaskets seals to withstand the heat and reduce friction,

engine air management is performed with an ISO valve (2), scheduled for 10 million cycles, like indestructible within the diving use market. If ever this ISO valve malfunctions, being a standard in the industry, it can be found very easily anywhere in the world.